In various wood processing plants, a large number of wood chips with different shapes will be produced during the process of wood processing by all kinds of woodworking machines. These wood chips are generally wood shavings, sawdust, wood fiber, and wood powder.

Owing to the dust’s small density, ordinary masks cannot play a protective role in isolating wood chips. If workers inhale too many wood chips during operation, they will cause significant harm to the lungs. Therefore, it makes sense to use the industrial dust collection system.

Furthermore, the other benefits to equip with an industrial dust collector are that it ensures the successful progress of wood processing, improves the quality of the product, and protects the workshop’s surroundings to prevent pollution and fire.

There are different types of woodworking machines in the wood processing industry, so do industrial dust collectors. It has necessary to understand the application cases of various dust collectors. In the next part, I will introduce different types of woodworking machines and their matched industrial dust collectors.

Main types of woodworking machines

Woodworking milling machine

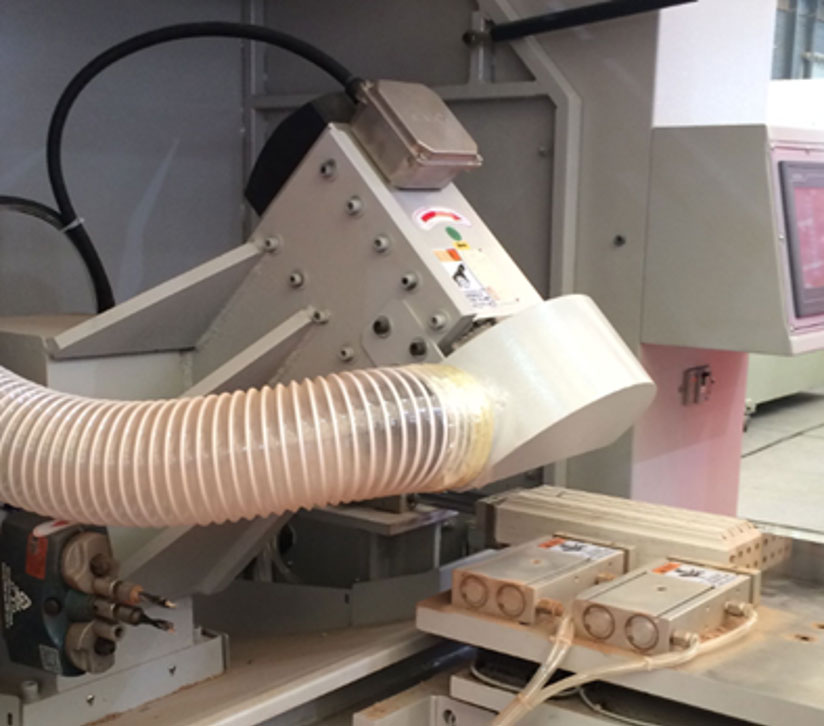

A woodworking milling machine is to use high-speed rotary milling cutter to slot and tenon the wood. Generally, due to the particle size of the dust generated by the milling machine is large, a shield with a dust suction port will be set in the milling cutter’s direction of rotation.

The auto discharge industrial dust collector is usually selected to collect large wood chips generated by the milling machine. Thus, you can choose the appropriate auto discharge industrial dust collector according to the dust suction port’s diameter.

Drilling machine

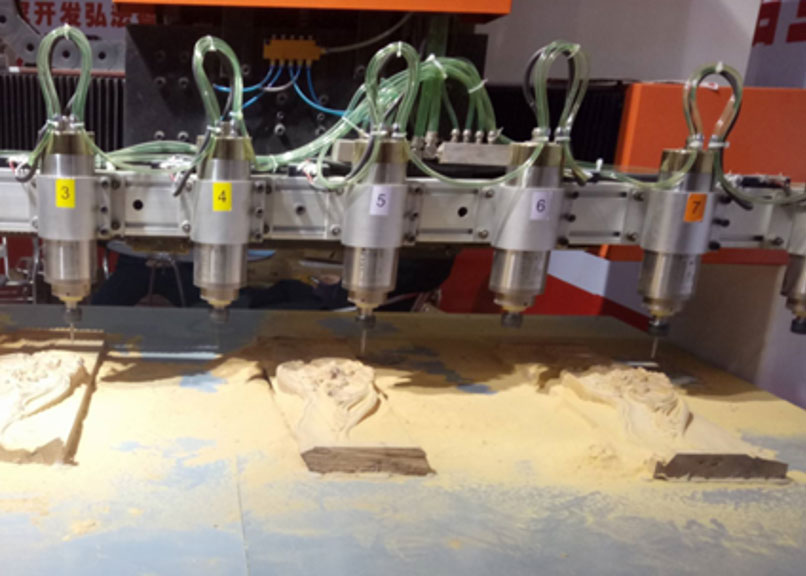

A drilling machine is to use a high-speed rotating bit to machining. A large amount of debris and dust will be produced in the process of drilling with wood. Larger particles of debris will fall to the table and ground, while dust with smaller particle size will float in the workshop.

The truth is that there are brushes that are fixed on the dust hood around the drill bit. When the drill bit moves along with the path set by the system, the brush, and the dust hood follow. The dust collector pipe is connected above the dust hood to collect the floating dust and the dust remaining on the surface. The auto discharge industrial dust collector is also applied in this case.

CNC cutting machine

A CNC cutting machine is automatic equipment that can automatically position, feed, and accurately cut the plates after the instructions input by workers.

As the wood chips produced by CNC cutting is generally large in particle size, the worker will use the auto discharge industrial dust collector to collect wood chips. And the shield with a dust suction port will be set in the saw blade’s direction of rotation.

Sanding machine

The sanding machine is to polish the surface of the workpiece by using an abrasive belt and abrasive cloth (paper). The small size of floating dust will be produced in the process of sanding.

Due to the fine dust and spark generated by such a process that will have accumulated temperature, selecting the explosion-proof industrial dust collector with a hard pipe is necessary. The lengthen the pipe needs more than two meters, and a spark catcher should be set in the pipe.

A dust suction port is designed on the top of the sanding machine or above the grinding wheel, so you can choose a suitable explosion-proof industrial dust collector according to the diameter and quantity of the dust suction port.

Conclusion

The industrial dust collector is widely used in the wood processing industry. Almost every process is inseparable from the industrial dust collector. Since the industrial dust collection system exerts a significant influence on the wood processing industry, we should choose a reliable industrial dust collector manufacturer to ensure the woodworking work.

Recently, we learned that a Chinese brand, Villo, has won a mounting number of customers’ praise. Villo is the leading industrial dust collector manufacturer providing a variety of industrial dust collection solutions, including automatic discharge industrial dust collectors, explosion-proof industrial dust collectors, and so on. Try to make the right choice with Villo to guaranteed your worker’s health and the wood processing quality.